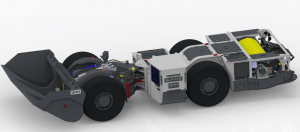

Loaders

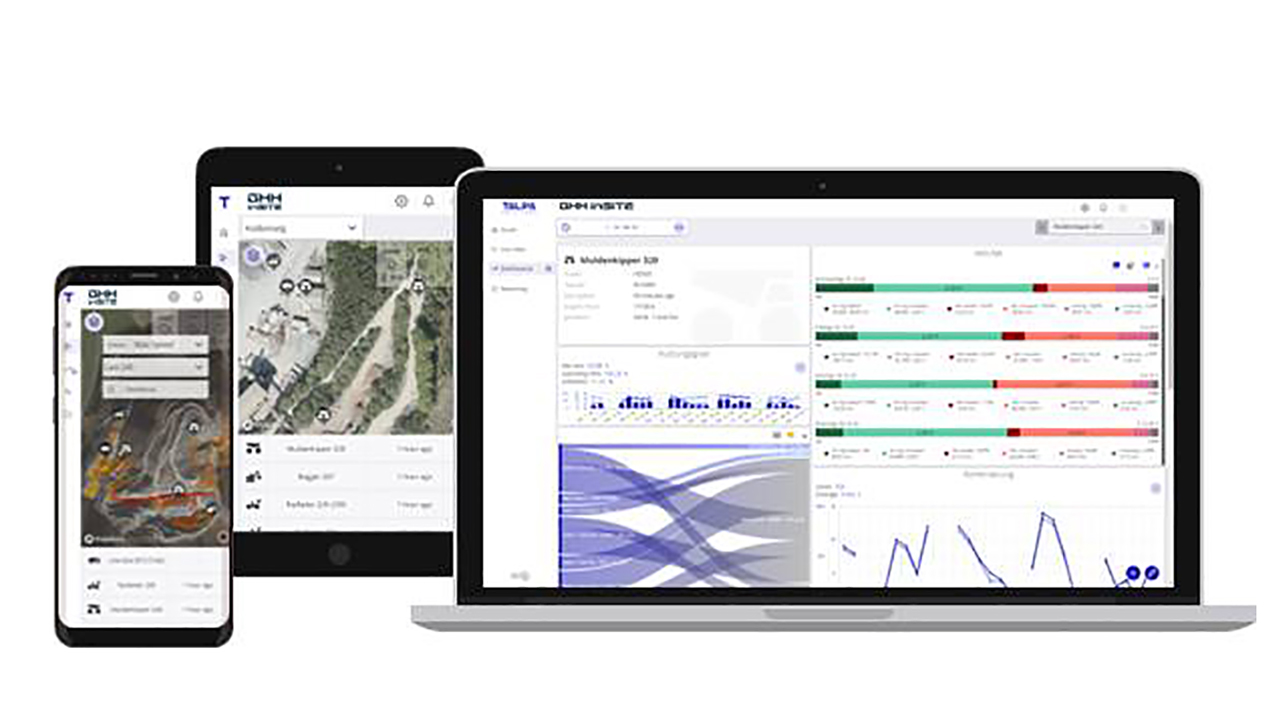

GHH Diesel LHDs are custom designed to operate in the low profile, narrow vein and midseam mass mining operations in both hard and softrock applications. They are efficiently compact with an optimal operator’s position. The lateral arrangement of the operator seat guarantees optimal views for forward and backward tramming. The capacities of the GHH LHDs are ranging between 1 to 21 tons. The LHDs are globally used in underground mining, in tunneling, hydro-power and other civil construction projects. Renowned for their robust, durable and reliable characteristics, the loaders are available in various emission standards and come with data analytics and automation capabilities. Safety, ergonomics and maintainability are some of the key features of our design.

LF-14 loader

LF-14 loader, a 14 metric ton loader, versatile, robust and reliable. Made not only for hardrock applications, but equally fit for operation in tunnelling and softrock applications.

The recently launched LF-10 NEO, will become part of the GHH product family, filling the gap between the LF7, LF-8 and LF-14 loaders. With the z-link design and highest tipping height in its class, and largest power rating, this loader becomes one to beat. Being able to load every 30 ton class truck on the market gives it a leading edge.

The large footbox, excellent ergonomically designed cabin with great visibility makes this a loader of choice for operators.

The LF-7, launched in 2021, will become the largest of the GHH narrow vein loader offering. With a z-link lift arm, various engine packages, closed and open ergonomically designed operators compartment, operates at maximum 25 % slope, PDS interface, data analytics …. Just some of the specifications to come.

In a drive to constantly comply to stringent engine emission standards the entire GHH loader offering has a significant amount of products available in Tier 3, Tier 4 final and Stage V packages to support industy drive towards environmental and operator friendly working environments.