Bolters

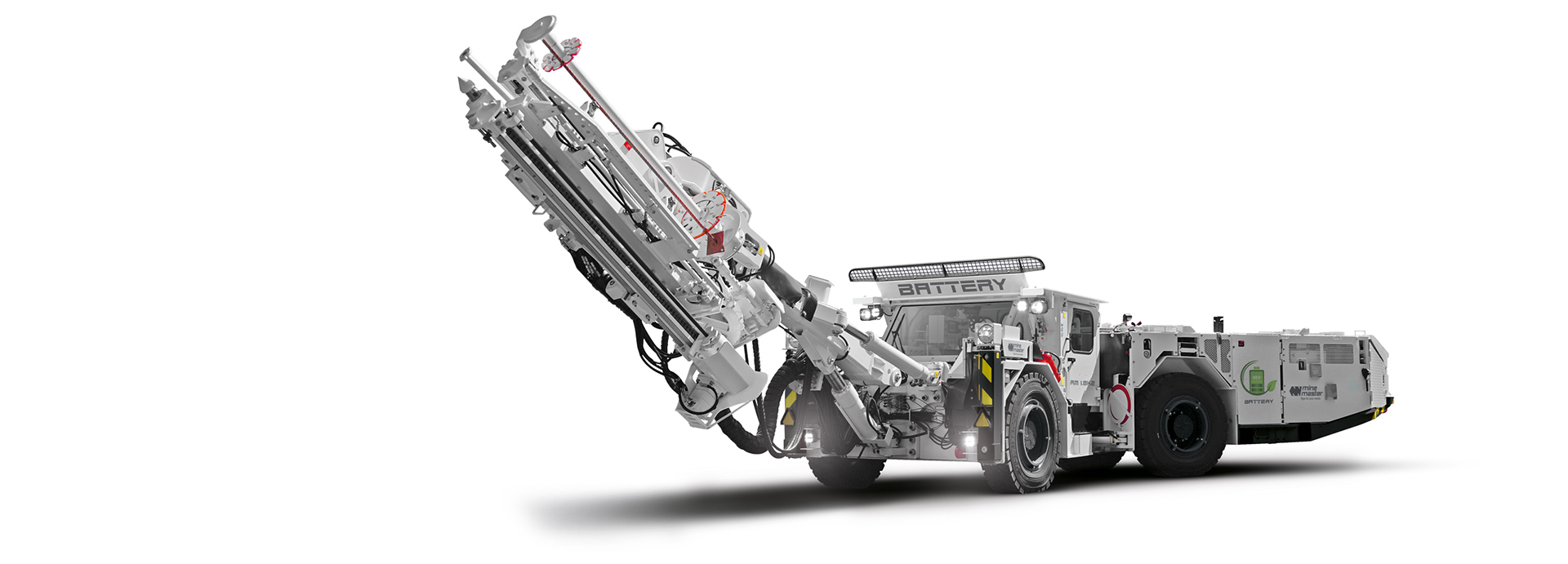

Roof Bolters are specialized mining machines designed for drilling holes and installation of safety bolts in roof and walls of underground mining excavations. Mine Master offers bolters that can successfully secure various types of mining workings, both in low profile mining applications as well as in large excavations. In the vast majority of variants of working units of bolting rigs the reliable and efficient rotary hydraulic drills are used. The Roof Bolters can also be equipped with an automatic anchoring system developed in cooperation with J. H. Fletcher company. The construction of each bolting rig and its working unit is tailored to the individual requirements of the customer

| Product | Length | Width | Height | Weight | Max. Bolting height [m] | Operation | Min. width of heading for tramming @90 | Rockdrill | Power source tramming/working | Application | Spec Sheet |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RM 1.4 | 10.5 m | 2.4 m | 1.4 m | 18.4 T | 3.3 | On the left side of the boom | 4.5 | Rotary with dust collection | Diesel/Electric | Non-flameproof | – |

| RLP 1400-1B | 10.1 m | 2.4 m | 1.4 m | 19.7 T | 3 | On the left side of the boom | 4.5 | Rotary-percussive | Diesel/Electric | Non-flameproof | – |

| RM 1.7 | 11.3 m | 2.4 m | 1.7 m | 19.5 T | 4 | On the left side of the boom | 4.5 | Rotary with dust collection | Diesel/Electric | Non-flameproof | – |

| RM 1.8 KE | 13.6 m | 2.4 m | 1.8 m | 24.5 T | 4.8 | From operator’s compartment | 4.4 | Rotary | Electric batteries | Non-flameproof | – |

| RM 2.3 AWK | 11.3 m | 2 m | 2.4 m | 20.5 T | 8.3 | From operator’s compartment | 4 | Rotary-percussive | Diesel/Electric | Non-flameproof | – |

| RM 2.6 AWK ATEX | 14 m | 2.4 m | 2.6 m | 28 T | 7.5 | From operator’s compartment | 4.5 | Rotary-percussive | Diesel/Electric | Ex/Flameproof | – |

| RM 2.3 | 12.7 m | 2.6 m | 2.3 m | 29.7 T | 9 | On the left side of the bottom/ from operator’s compartment | 4.5 | Rotary percussive | Diesel/Electric | Non-flameproof | – |

With the ever growing need for reduction in greenhouse gases Mine Master has been working on a new battery platform design for intial implementation into the RM1.8KE. The has a resultant noise reduction, no gas emissions and provides for energy recuperation during braking and driving down slopes. Incorporating all the best features of the current products and improving the drive train design to cater for the modular battery package platform integration. Add block